Where to Buy CO2 Laser Cutting Machine?

To an ever-increasing extent, CO2 lasers are being utilized in present-day cutting-edge fabricating. This is a decent utilization of CO2 and as we attempt to dispose of CO2 in our air gathering it from the smokestacks that may be of electrical energy age, it turns into a modest and important gas for running these lasers. Presently then, at that point, CO2 lasers put out a nice measure of intensity. We ought to gather that intensity, intensity ought to never be squandered. He ought not to be squandered it from automated plant welding machines or from lasers. Alright so we should talk for a second, co2 laser cutting machine for sale will we? The most widely recognized kind of laser shaper that anyone could hope to find in the industry today is the CO2 laser. It offers benefits over different sorts of lasers for reducing expense, proficiency, and power accessible and has turned into the business standard.

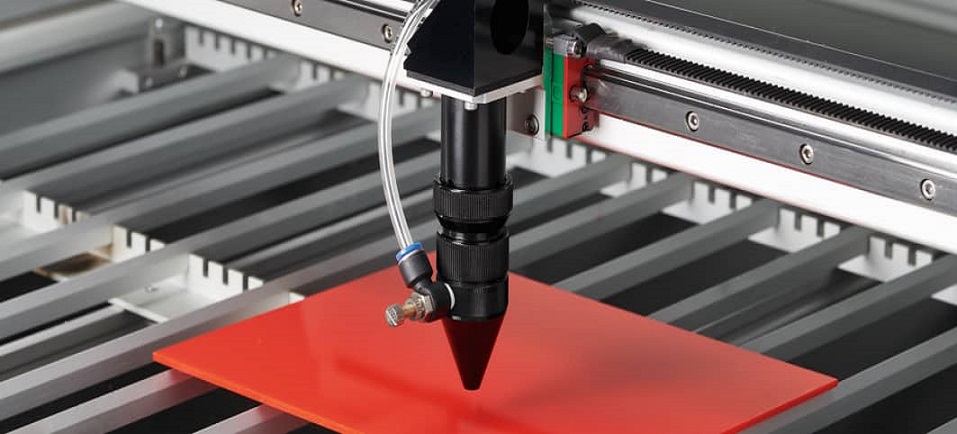

How CO2 Laser Cutting Machine Works

The laser can be utilized to cut a wide assortment of materials. With a laser cutting machine, paper and plastic can be effortlessly cut much definitively. Indeed, even pressed wood up to 1″ thick can be cut by this machine. Cutting metal sheets also can be utilized. Normally force of the laser is regulated to choose different levels of cutting.

Little mirrors are utilized to direct light from the laser to a specific area of the material. The foundation of the cutting region is produced using a honeycomb material to allow the laser to light go through. This must be supplanted intermittently.

Laser cutting machines are particular from conventional mechanical cutters. Since the laser never connects with material and there is less of an open door for the material to become polluted. Laser cutting machines likewise cut material with higher accuracy than that mechanical means. Besides its benefits over customary mechanical cutting, laser cutting is a peaceful interaction. Well-being is likewise significant and, thus, most laser machines are completely encased to forestall mishaps.

Utilizes

CO2 laser framework can be utilized anyplace the more customary cycles, for example, oxy and plasma cutting are utilized. In any case, a CO2 laser shaper enjoys the benefit of having the option to cut a more extensive assortment of materials like plastics and wood. CO2 lasers can be mounted on different movement frameworks from little work area units for little work, to enormous gantry frameworks for cutting huge plates, to robot arms for 3D cutting.

Only a couple of the wide assortment of uses for CO2 laser cutting is profiling of steel shapes, cutting or boring of openings in steel parts, cutting of dainty sheet metals, cutting of plastic signs and covers, cutting of profiles in wood, and cutting of textures and plastic movies.

Types of CO2 Lasers

The essential sorts of CO2 lasers are separated into three. First is the hub gas stream which siphons the carbon dioxide, nitrogen, and helium blend from one finish of the cylinder before it goes out to the next. To ensure that the stream is kept up with, carbon dioxide is siphoned ceaselessly into the cylinder. The job of nitrogen and helium in the process is to improve productivity. This CO2 laser’s length might be decreased through the assistance of collapsed optical frameworks.

There is likewise a cross-over gas-stream CO2 laser. The gas stream for this cycle is done on a level plane. It is equipped for creating higher power yields from the higher cylinder pressure. A third kind known as the fixed cylinder is likewise accessible. This one is like fixed helium and neon and fixed argon and krypton lasers. There is no topping off made during the cycle.

Development Materials for CO2 Lasers

Other than these sorts are different development materials to observe. Mirrors, for instance, utilize silicon, gold, and molybdenum – which are all covered. For windows, germanium and zinc selenide are utilized in development. In certain occurrences, jewels may likewise be utilized in window or mirror creation. A portion of the optical components created was generally made from sodium or potassium chloride. Presently, these materials are not generally utilized on the grounds that in spite of its minimal expense, the result corrupts rapidly, particularly when dampness is available in the climate.

For the most part, CO2 lasers are utilized in cutting, heat treating, etching, and welding. They are additionally significant in the development of cardboards, textures, paper, plastics, wood, and earthenware production. Moreover, they can be utilized in clinical fields explicitly in the realm of dermatology. Laser medical procedures, dermabrasion, and skin reemerging are not many of the models in this application.